05/08/2025

In the world of modern materials, where product quality demands are becoming increasingly strict and consistent, Frit has emerged as a superior technical solution — especially in the production of ceramic glazes, glass, metal coatings, and industrial electronics. With its stability, ease of control, and ability to enhance production efficiency, Frit is becoming an indispensable material in the creation of high-value products — in terms of both quality and aesthetics.

1. What is Frit? – The Essential Material Behind Ceramic Glazing

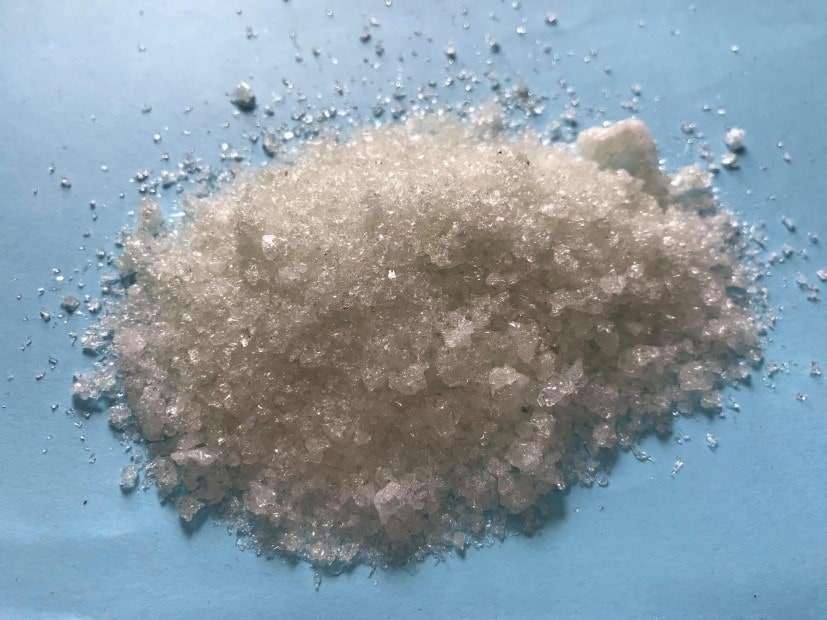

Frit is a special type of glass produced by fully melting a mixture of raw materials (including oxides such as silica, soda, boron, alumina, titanium, etc.) at high temperatures of around 1500°C. The mixture is then rapidly cooled in water or on a metal surface to create small, brittle glass particles that are insoluble in water and can be ground into fine powder.

This melting process eliminates toxic impurities, stabilizes chemical composition, and improves material consistency. Frit serves as an intermediate product used to create glazes for ceramics, tiles, metals, and glass — enhancing mechanical strength, chemical resistance, and aesthetic appeal in the final product.

2. Frit Production Process – A Fusion of Thermal Technology and Material Control

Producing Frit requires a combination of precise chemical blending and strict thermal processing. The basic steps include:

🔹 Step 1: Material Preparation

Main components of Frit include:

-

Silica (SiO₂) – forms the glassy matrix

-

Sodium (Na₂O), Potassium (K₂O) – enhance chemical durability

-

Calcium (CaO), Barium (BaO) – improve chemical resistance

-

Boron (B₂O₃) – lowers firing temperature, enhances gloss

-

Alumina (Al₂O₃), Titanium (TiO₂) – increases hardness and opacity

-

Zirconia (ZrO₂) – improves whiteness

The oxides are blended according to specific technical requirements for each glaze formulation.

🔹 Step 2: Melting

The batch mixture is loaded into a specialized furnace and heated to 1250°C–1450°C until fully melted into a homogeneous glass mass.

🔹 Step 3: Rapid Cooling

The molten glass solution is poured into a water tank for cooling or onto a cold metal surface. This rapid cooling process causes the glass to shatter, forming Frit particles that are small in size and structurally stable.

🔹 Step 4: Drying and Grinding

The Frit particles, after cooling, are dried to remove moisture and then ground into fine powder – serving as an important raw material in the production of ceramics, metal coatings, glass, and more.

3. Frit Classification – Versatile for Every Application

Depending on its intended use, Frit is classified by various technical criteria:

3.1. By Chemical Composition:

-

Alkali-containing Frit (Na₂O, K₂O):

Lowers firing temperature, increases flow, and improves adhesion — ideal for glossy, transparent glazes. -

Alkali-free Frit:

Used in applications requiring high chemical durability, insulation, or exposure to harsh environments.

3.2. By Surface Effect:

-

Transparent Frit:

Suitable for glossy decorative coatings, resulting in smooth and vibrant finishes. -

Matt Frit:

Creates a matte, non-glare effect — great for interior decor, floor tiles, and anti-slip surfaces.

3.3. By Industry Application:

-

Frit for domestic and industrial ceramics

-

Frit for tile production — both wall and floor tiles

-

Frit for metal coatings — corrosion protection

-

Frit for technical and medical glass

-

Frit for microchips, wafers, and electronic components

4. Applications of Frit Across Industries

🔸 4.1. Ceramic Industry

Frit is a key and essential raw material in the production of ceramics, tiles, and more, helping to:

-

Durable, uniform, and glossy glazes

-

Reduced firing temperatures, leading to energy savings

-

Stronger adhesion and hardness of the glaze layer

-

Enhanced color, clarity, and decorative effects

🔸 4.2. Glass Industry

Used in specialty glass production, such as:

-

Optical glass

-

Medical glass – heat and chemical resistant

-

Decorative art glass

Frit’s controlled chemical composition and viscosity contribute to improved glass stability and mechanical properties.

🔸 4.3. Metal Industry

Frit is used for coating metal surfaces like iron, steel, and aluminum, offering:

-

Protective enamel layers resistant to corrosion, acids, and alkalis

-

Extended lifespan and improved durability of metals

-

Enhanced aesthetics with colored and textured finishes

🔸 4.4. Electronics Industry

In microchip, wafer, and PCB manufacturing, Frit helps:

-

Join materials with different melting points

-

Create thin yet stable insulating layers

-

Improve performance and longevity of electronic components

5. Outstanding Benefits of Using Frit

Using Frit in production offers multiple advantages:

-

Reduced toxins: Frit converts harmful silicates into non-soluble, safer compounds

-

Better quality control: Stable composition allows for accurate measurement and consistent mass production

-

Cost and energy savings: Due to lower firing temperatures and improved glaze efficiency

-

Enhanced durability and aesthetics: Frit-based glazes offer strong adhesion, water resistance, and customizable finishes — glossy or matte depending on design needs

6. Phu Son Frit – A Trusted Industrial Frit Supplier in Vietnam

Phu Son Frit is proud to supply premium Frit products for a wide range of industries — from traditional ceramics and construction tiles to technical glass, metal coatings, and electronic components.

We offer:

✅ A modern, closed-loop production process with stringent quality control.

✅ An experienced technical team.

✅ Customizable Frit formulations to meet specific client requirements

✅ Competitive pricing – fast delivery – reliable after-sales service

Contact Information:

Frit Phú Sơn – Quality Builds Reputation

📍 Address: Lot CN17, Phu Da Industrial Zone, Phu Vang Commune, Hue City, Vietnam

📞 Hotline: (+84) 971 154 996

📧 Email: fritphuson.sales@gmail.com